Precision Machinery Manufacturing

Nomura CNC Automatic Lathes

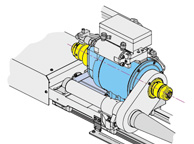

All types of Nomura CNC Automatic Lathes use a headstock which moves during fabrication. These are often referred to as Swiss-Type Precision Automatic Lathes.

The main spindle tip grips the workpiece with a collet chuck, and the headstock moves axially, receiving the guide bushing located in the center of the tool post. Lathe cutting occurs at this orifice. This process avoids creation of vibration or deformation, allowing consistent, high-precision manufacturing.

As most of our products use our company’s own original tool presetter system, the user’s tooling changeovers are quick, contributing to increased production efficiency.

Minimizing the Number One Lathe Cutting Obstacle – Vibration.

50 years of amassed design techniques and commitment to manufacturing quality give Nomura DS Automatic Lathes their remarkable ability to reduce vibration – the number one problem faced in lathe cutting work.

In order to maintain long-lasting micron-level cutting precision, we believe it is necessary to offer "Workmanship, part precision, material quality, and most of all, the integration of our technological strengths to create total machine balance".

Making use of 50 years of integrated technical knowledge, we offer the utmost in vibration reduction by:

- Utilization of "slide guideways" crafted by "scrapers" to provide high rigidity of the tool rest.

- Custom-casting of the metal for optimal scraper fabrication of the slide guideways.

We appreciate the worth of quality materials and workmanship – that is NOMURA-ism.

A Harmony of Ideal Environment and Crafter's Skill

In order to create high-quality, reliable products, the highest standards in development, design, manufacture, and quality control are melded, resulting in a "mother machine".

50 years since our first efforts, we still continue precision fabrication techniques which carry on the tradition of "Nomura Spirit". These techniques are backed by dedicated artisans in an ideal environment, making "High Precision", "High Rigidity", "High Durability", "High Reliability" products a reality. This is culmination of the effort and dedication of numerous crafters.

We salute the passion and dedication of these artisans who work behind the scenes to support high-precision fabrication technology, as well as the next generation of artisans who will carry forward this craft. At Nomura, we are proud to carry this unbroken tradition to our products today.

"It Takes Good People to Make a Good Product!"

No matter how advanced the technology used to develop new products is, it is not possible to maintain quality without the techniques and skill for fabrication and assembly of those products.

Even assuming that the assembly is done exactly according to the design drawings, without sophisticated skill, the result will be a nonstandard product – something different entirely.

Without artisans dedicated to "monozukuri" – the art, craft, and science of relentless improvement of manufacturing process – submicron-level precision would not be possible.

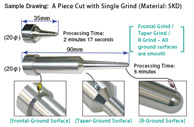

Cut Even SKD Steel Beautifully, the First Time

Even when cutting hardened SKD steel (commonly known as "tool steel"), reliable cutting can be achieved with a single pass (using lathes such as NN-UB or YB series).

Sound design and exceptional dedication to manufacture have enabled us to reduce vibration to the utter minimum. This is why even extremely hard and durable materials up to SKD steel can be cleanly and precisely cut. Our clients have come to expect this level of Nomura quality.

Scraper Technique – Essential for Reliability

Even during the manufacturing process, some areas are too fine for machine cutting. For these areas we employ the "scraper" techniques of highly-skilled crafters.

This is yet another technological strength that we employ to complete products which our customers can trust.

- Scraper Technology

- This is a traditional technique with about 200 years of history.

Fabrication of ultrafine features (precise to submicron levels of 0.0001 mm) can be achieved. The scraping work is performed by hand. The precision of our state-of-the-art machine tools is born from the hand work of skilled artisans.

Nomura’s scraping method effectively distributes load, increasing surface ratios and leading to less contact pressure over area, leading to remarkable abrasion resistance. The result is precision that remains reliable more than twice as long as that from ordinary scraping methods.

Specially Selected Materials

The "scraping" process mentioned above is performed by hand, meaning it becomes difficult when using harder materials.

In order to fill the tall order for materials that are "soft enough to apply scraping methods, and also do not wear down on contacting surfaces", Nomura DS specifies the constituent of the steel received from our supplying foundries (steel manufacturers).

After our previous research made it clear that steel casting performed to the basic JIS standard would not result in "slide guideway surfaces" that will live up to the high expectations of our customers, we have adopted this method.

Utilizing special materials increases our costs, but we see this as a critical element to the long-term maintenance of our superior "slide guideways".

Strength and Precision of Each and Every Part

The tool post, the tool table...we demand strength and precision from every part.

Amidst an industry-wide rally to cut costs, our foremost dedication is to "strength", "part precision", and "material quality" for all parts such as tool posts, tool tables, and our extremely high-precision spindles. This is why our customers can count on Nomura machinery to provide precise fabrication and beautifully cut surfaces, time and time again.